1, the main control circuit adopts Japan Panasonic PLC,Taiwan Delta inverter, ltaly datasensor color label tracking photoelectric joint control, to ensure that the system executes the control procedure with high precision.

2 independent innovative design, so that the gourd bubble, air pillow together, through the simple change of mold free to do any product. Large platform, double sets of easy to tear knife, can be combined according to demand, easy to switch. Smooth operation,high speed.

3,excellent man-machine interface and temperature control module, the interface is clear and intuitive, centralized and convenient operation.

4,speed display, length display, automatic counting, batch counting, fault-display, no material alarm and stop in advance, temperature alarm screen is clear and intuitive, easy to operate.10, large platform double mold hot pressing, double station easy to tear device,double mold double easy to tear knife can be combined according to demand, easy to switch.

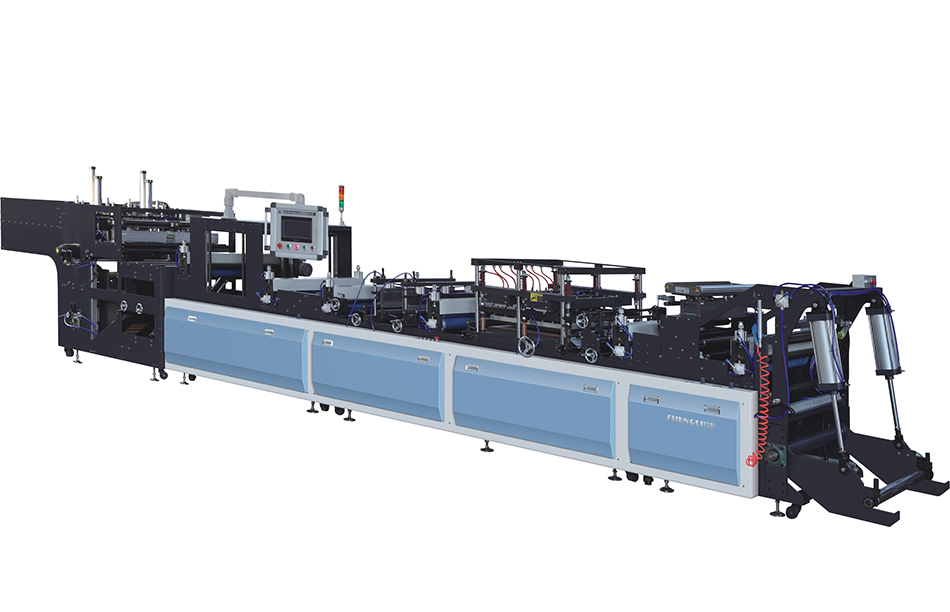

Main technical parameters

| Die length | 850mm |

| Maximum winding diameter | Φ1000mm |

| Inflatable shaft diameter | Φ74mm |

| Packaging film material | PE, PO, PE+PA coextrusion film |

| Receiving station | 2 bits |

| Maximum receiving diameter | Φ250mm |

| Pass rate | ≥99% |

| Column velocity | 90-150 m/min |

| Sealing pressure | 7560N |

| Width of die plate | 335×2 |

| Machine noise | ≤55db |

| Total installed capacity of the machine | 40kW |

| Gross machine weight | 6500kg |

| Machine dimensions | 9900mm×1690mm×2000mm |

| Power source | AC 380V 50HZ |

| Air source | Rated flow 0.8m3/min rated pressure 0.6-0.8MPa |

Obtained a number of national invention and utility model patents